Pombox - the pomodoro lock box

Hang up & hangout

Pombox started as an initial attempt to scratch my own itch and reduce my compulsive smartphone usage.

I was incessantly checking my phone, crippling my focus, emotions, & and mental health.

After trying different apps to limit screentime with no success (all were too easy to override), I knew I needed a way to physically block me from my usage.

"Out of sight, out of mind" was my mantra.

In my case, I needed to break the addiction cycle of my smartphone by remove the visual cue/trigger (i.e. smartphone).

I made a rough prototype out of cardboard just to get an idea of sizing, etc.

First pombox prototype

For those wondering: Pomodoro + box = Pombox

(FYI, the pomodoro technique is a time management method designed to break work into a 25:5 work/break intervals)

I thought "cool, I have a cardboard box, but how is it going to work?"

Keep in mind, I had ZERO, and I mean ZERO technical background (I literally thought that doing software updates on my PC was considered "technical").

So I went on Upwork, made a job post of what I thought I needed, and found a guy in Pakistan to make an Arduino prototype for about $400.

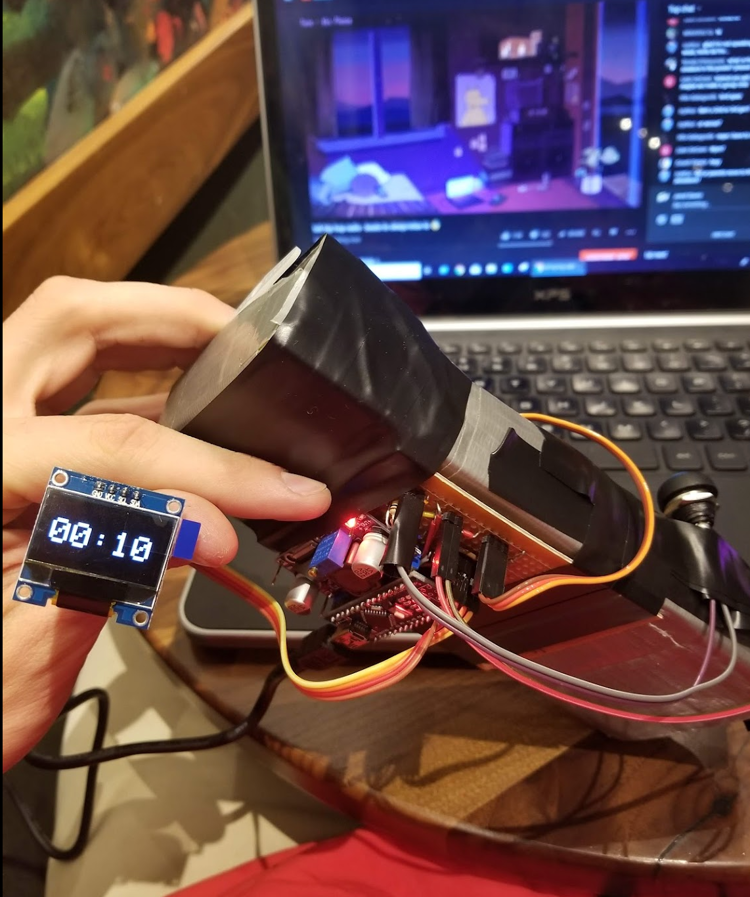

It was very basic, but I was so new, it seemed overwhelmingly complex. Luckily my dad can be quite technically handy, and he walked me through some of my hiccups.

Assembling Arduino pombox prototype

Inspiration comes in many forms - thank you Nutella.

Once I had a working prototype on a breadboard, I moved quickly to size the electronics down, and then move it to something a bit more durable than a cardboard box.

My solution was two-fold:

1. Breadboard -> soldered perf board

2. Cardboard -> plastic pencil case (found on clearance isle @ walmart for about $0.89)

Assembled first prototype at a Starbucks coffee shop. Lesson learned: don't assemble prototypes that look like improvised explosive devices (IEDs) in public places - people don't like that.

This model worked, and I was so happy I shed a couple of tears of achievement.

To back up, here's the main components of this protoype:

- 1x Arduino nano

- 1x 128x32 OLED display (for time/mode display)

- 3x tactile switches (for lock time increase & settings toggle)

- 1x mini servo motor (locking mechanism)

By now, I realized I needed to do something that would semi-reflect a real product. No more cardboard, duct tape, and pencil holders.

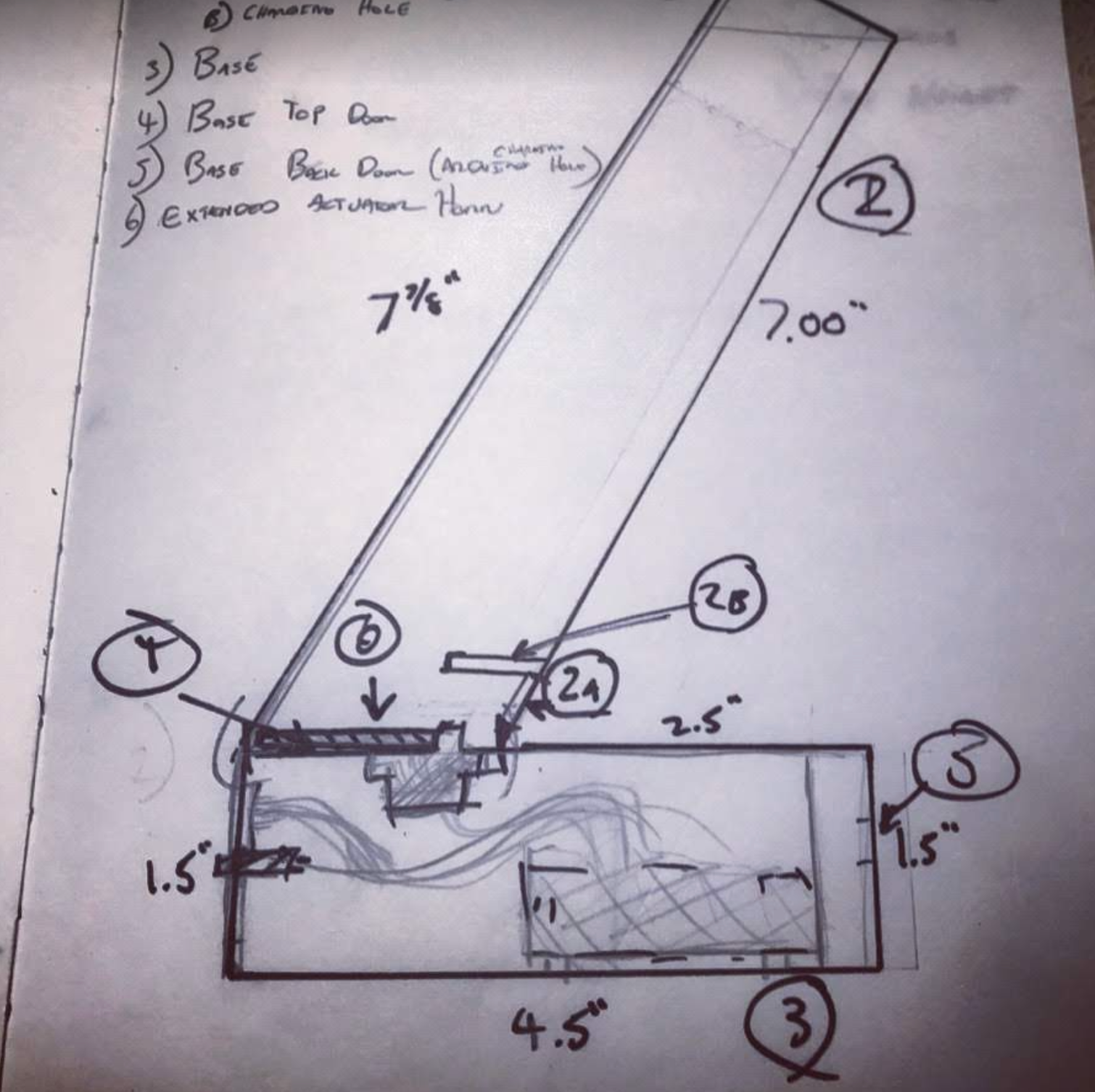

Made some sketches of what I wanted, showed my dad and asked for his help to make a CAD model to 3D print.

At this point, I had never 3D printed anything before, much less knew anything about CAD modeling. His help was crucial

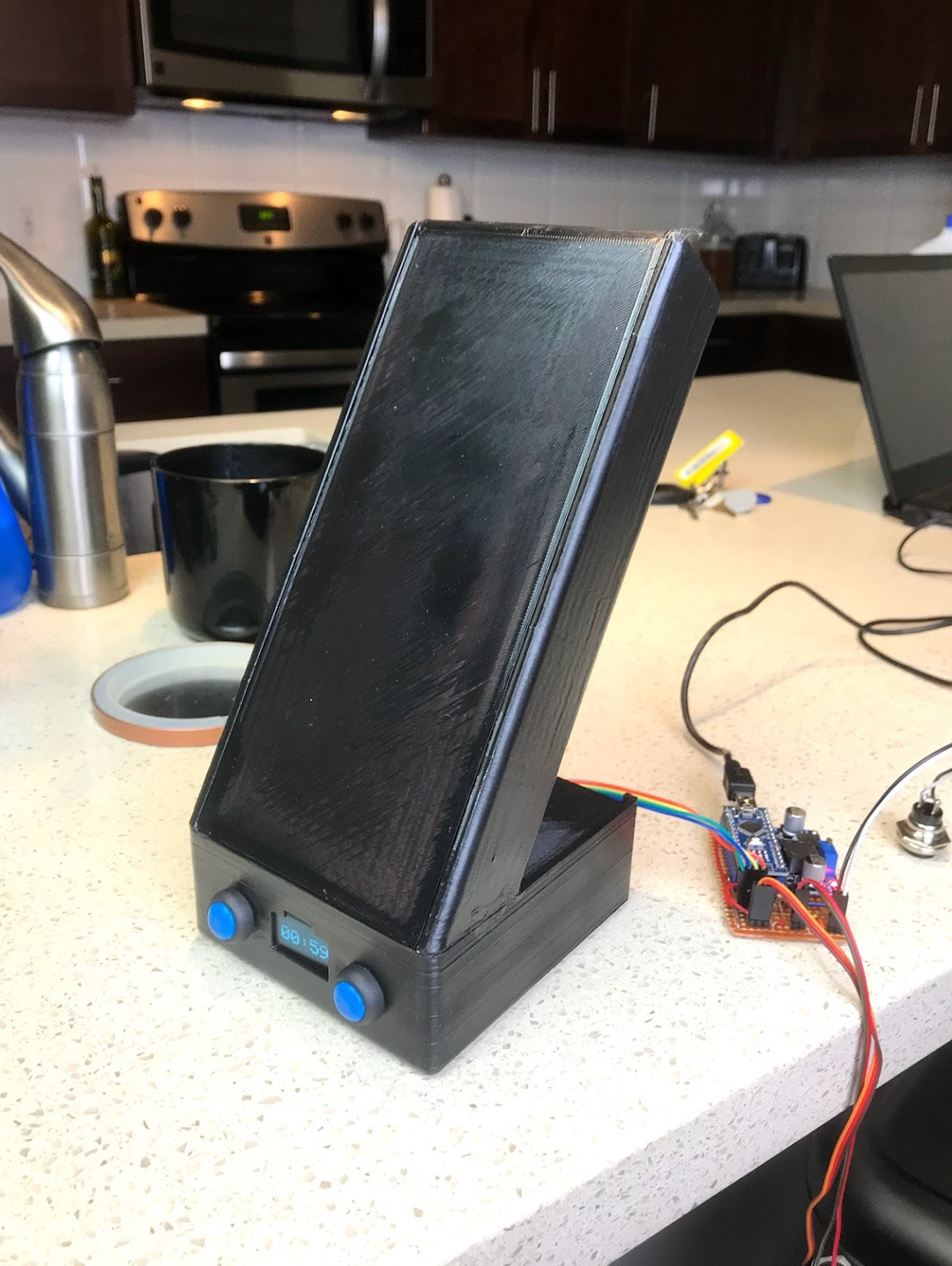

First 3D printed Pombox model. Looked like & was constructed like a tank. (12/27/2018)

Very soon, I realized this wasn't the product I envisioned. I made changed. TONS of changes you'll soon see.

I learned the importance of building a product to spec: it doesn't need to be perfect (perfection is usually subjective anyways), and shipping it on time.

Sketch of Pombox redesign.

The months that followed was a lot of design iterations. Getting this thing in the hands of friends, family, or co-workers, and just asking their thoughts.

Unfortunately, this led to way more confusion that it helped (making something for everyone is akin to making nothing for no one). So this is what partially caused a spiral of seemingly endless design spirals.

Redesigned model with some modest finishing. (note, arduino moved to perf board to consolodate space)

Thought this was the coolest thing in the world - didn't realize how cringe I was lol

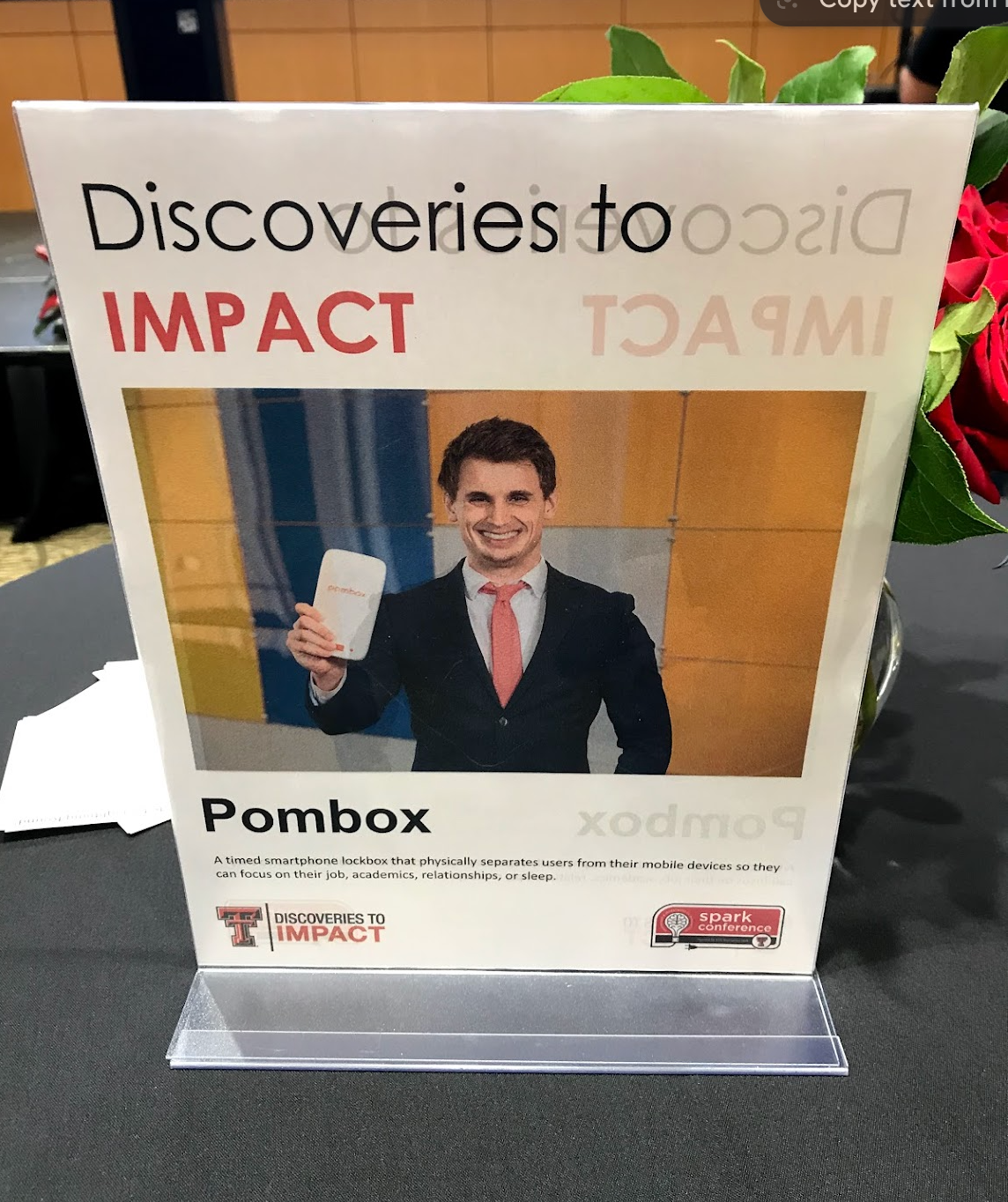

ast forward a couple of months, I redesigned the product to be more ergonomic & visually appealing. This redesign helped me get some recognition for an accelerator program at Texas Tech University.

Put together a really strong pitch & story behind Pombox. Lesson learned: passion, enthusiasm, and effort go a LONG way for getting others to buy in to your vision. (Discoveries to Impact: Spark Conference @ TTU Innovation Hub)

At this point, I was prompted to apply to the TTU Innovation Hub Accelerator by Kimberly Gramm (current Associate Vice President of Innovation & Entrepreneurship at TTU).

"You have what it takes to build this product to a $1M/year business - you just need to decide you need to".

They told me they would give me $ to prototype and experiment, and ultimately grow Pombox. Seemed like a no-brainer.

The top piece of feedback I got about the product is that the plastic "looked cheap" and maybe like a premium hardwood would help it's percieved value.

With that information, I went ahead and moved forward with wood designs. I utilized the lazer cutter at the Dallas Makerspace and hot glued some models together.

Plasma-cutting components for the Pombox redesign (6/3/2019)

Assembling components from plasma-cutter.

New Pombox redesign

Of course, like most young & naive founders, my focus was on looking cool. Not improving the product or sales. So i did the logical thing and spent an afternoon making a fancy LED logo sign with my new plasma-cutter skill 🙄

Plasma cutting pombox logo

Pombox LED logo

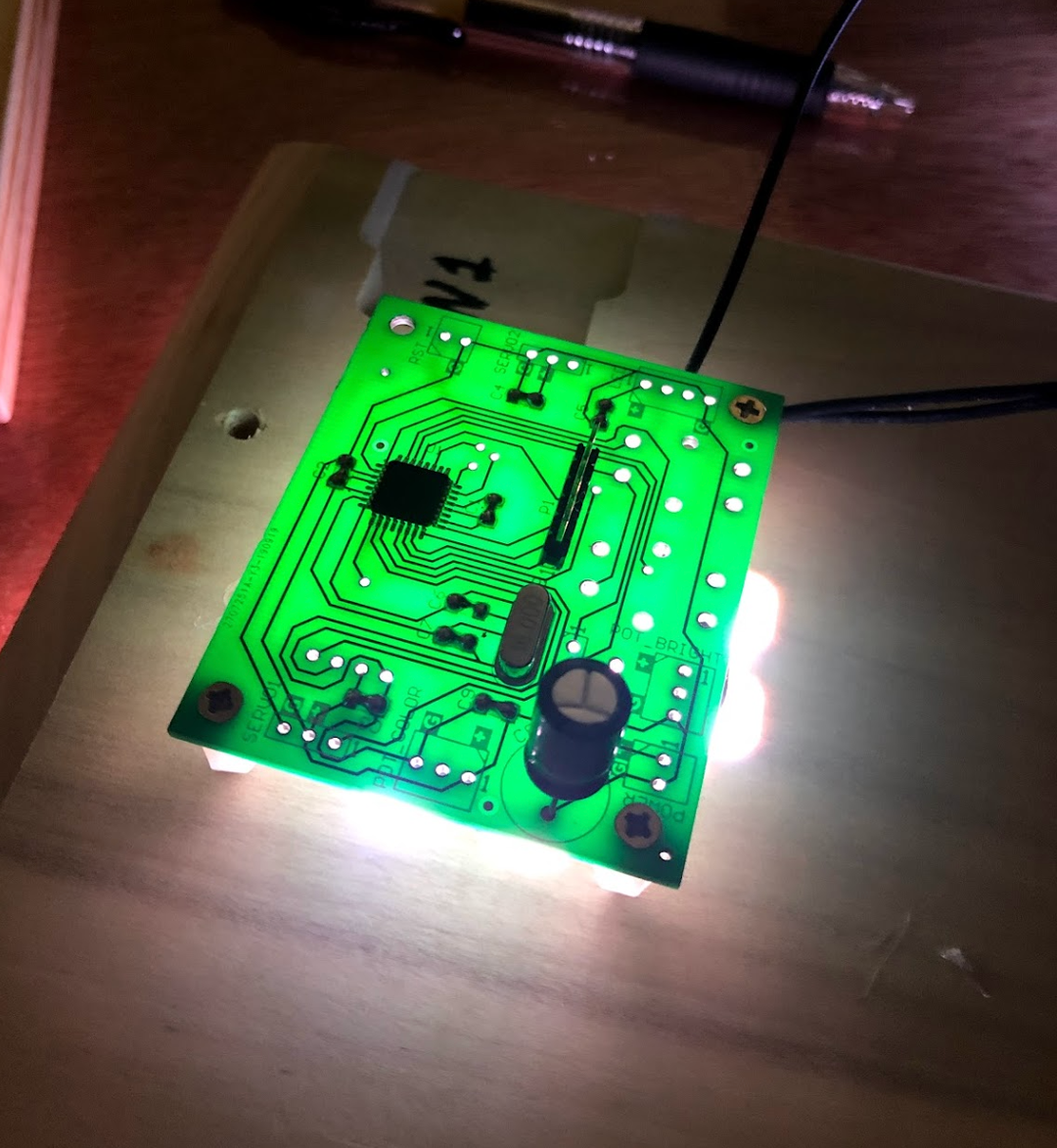

From there, I decided to make the electronics system on a printed circuit board (PCB). This was totally new territory for me, so of course I went to Upwork again and hired a guy to help cover this.

It took a couple of revisions, a new understanding of how electronics actually worked, and ultimately buying a stack of 25 PCB's from Shenzen, China with my schematic on it.

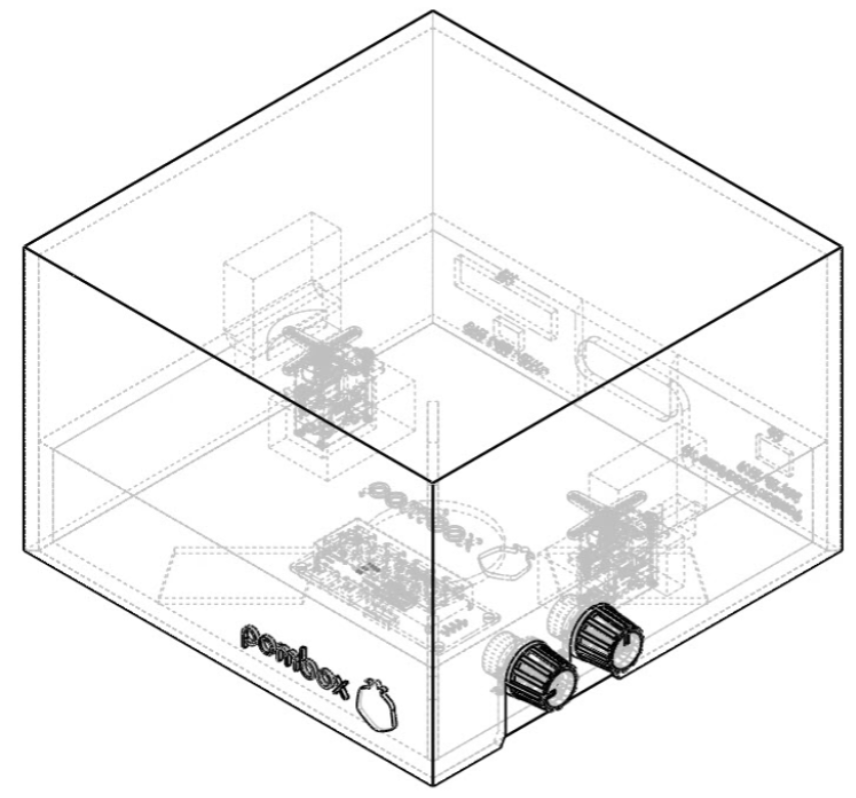

Pombox CAD model (migrated electronics from Arduino/perf board -> Printed Circuit Board (PCB))

New PCBs

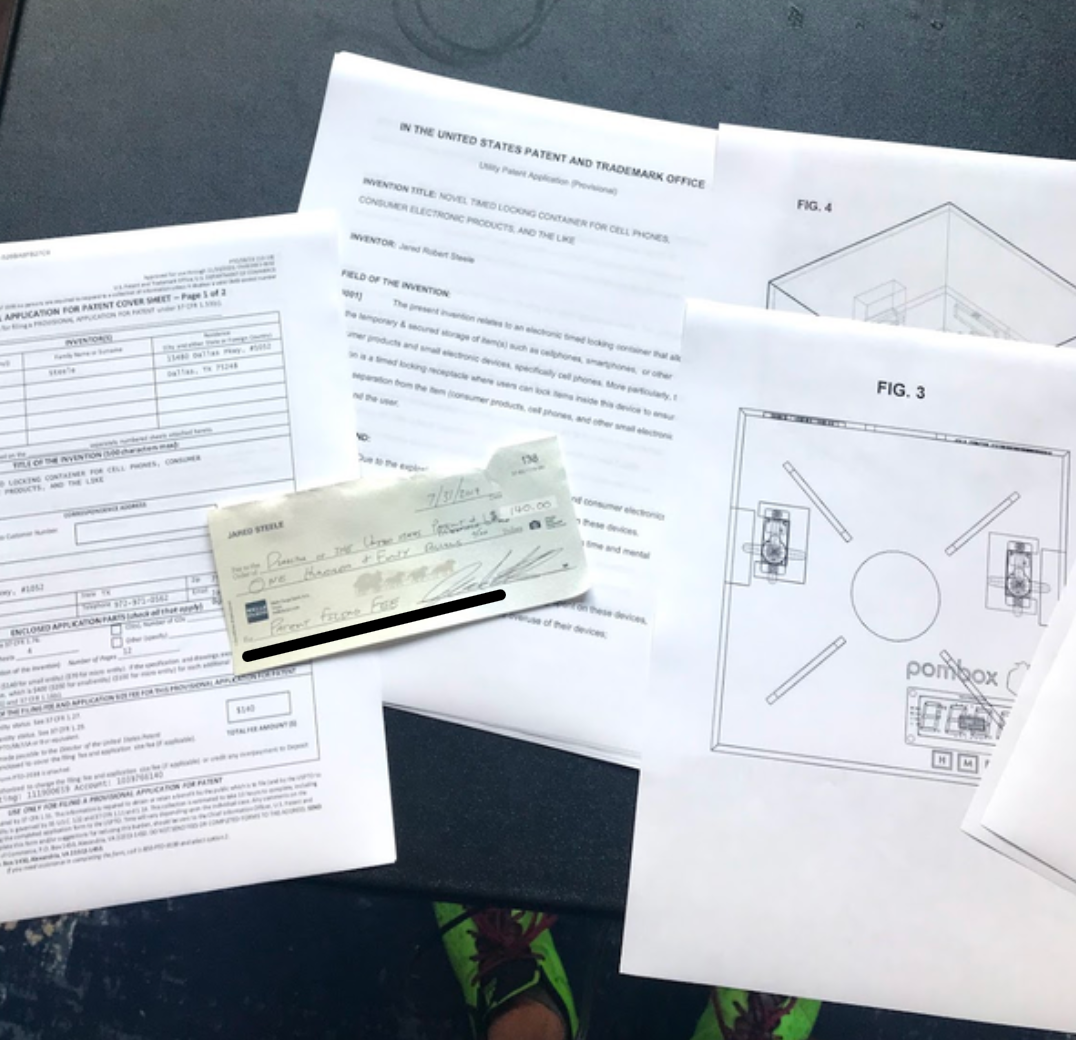

Submitted a Provisional Patent Application with the United States Patent & Trademark Office (USPTO)

Presenting Pombox for TTU accelerator

Used a CNC router (MultiCAM) to precision cut pombox components for final design assembly

Assembling the wood redesign model with PCB + CNC router parts.

Had my friend Alvin Kim fly in from LA to do a product photoshoot for Shopify store.

Alvin Kim (https://www.alvinyjkim.com/) is a college buddy and incredibly talented photographer.

He flew in from LA to do a photoshoot for the newly launched Shopify store. Being small, we used whatever resources we had for proper staging:

-My bedroom

-The model room at the apartment building I was living in

-IKEA

-Dallas Makerspace

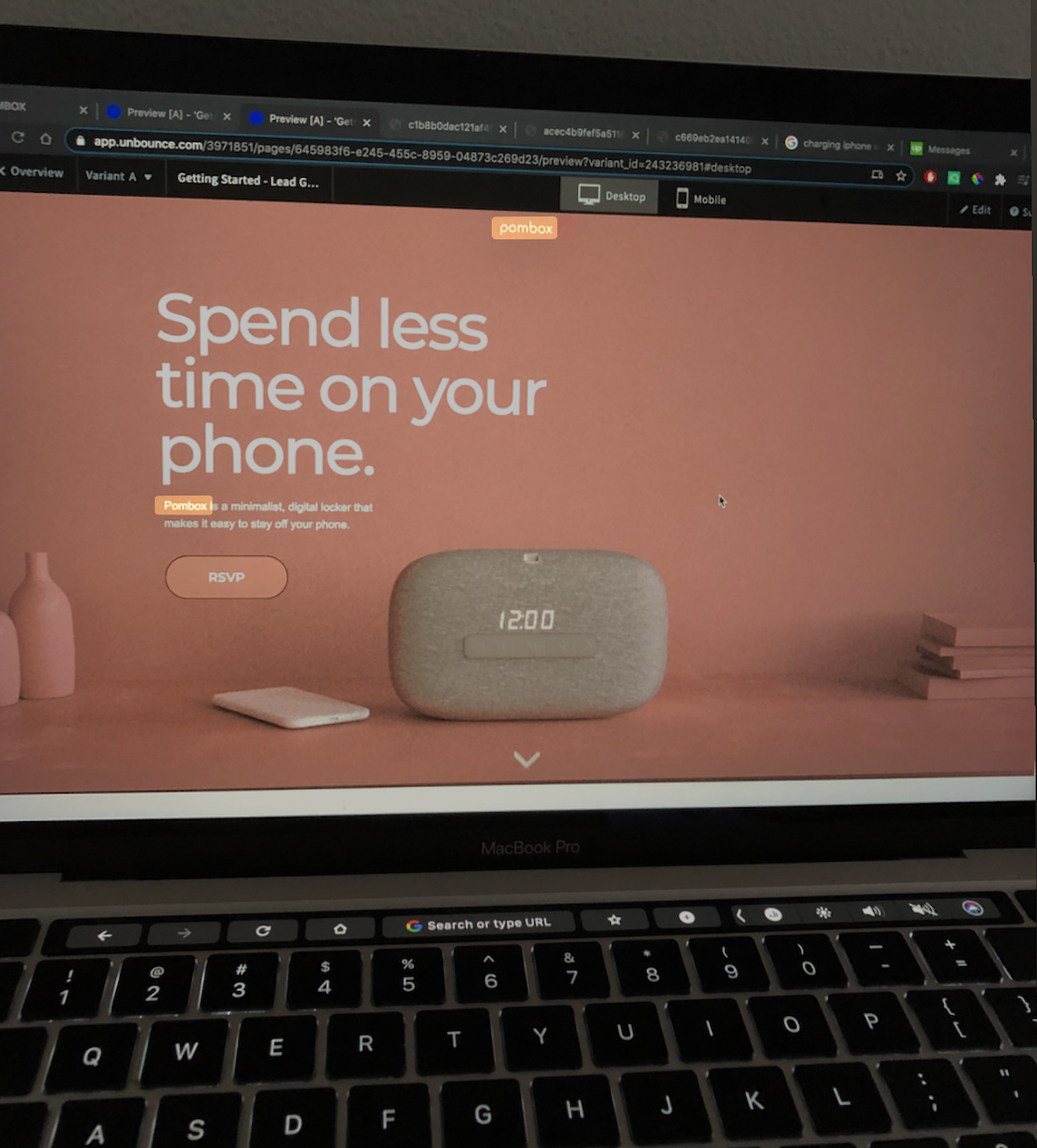

The result of the new photos gave a huge boost. I still wasn't running facebook ads and was just prepping for a launch on Kickstarter or Indiegogo, and wanted to test how receptive potential customers were with a nice website with a well-presented product.

The result was pretty incredible.

Google's SEO algorithm liked the photos or something, and in the next few weeks, thousands of dollars in orders came pouring in from SEO traffic.

I was completely caught off-guard, but went to work assembling these products and fulfilling orders.

Soldering components (transistors, capacitors, LED module, potentiometers, etc.) onto PCB for orders.

Working PCB with LED WS2812b LED module for underlow light

Components from the MultiCAM tool, ready for assembly

Assembling outer shell components

Alvin came out for the product assembly. Such a fun day.

Assembling + staining the base component (This is what housed the PCB, potentiometers, seven segment display, LED ring light, locking mechanism, etc.)

Soldering + assembly + uploading firmware

QA testing the electronics before shipping out to customers

Orders to ship out

After orders shipped out, I was pretty burnt out.

This was an incredibly manual process, and thankful that I learned a lot. Working 90+ hour weeks for a couple thousand dollars was dumb.

This was a tough period of life; I learned, grew, and opened my eyes to the world of hardware.

Went from zero experience/knowledge, and learned a substantial amount about the product design + ecommerce process. Skills I learned from this: -Hardware prototyping

-3D printing

-Plasma-cutters

-CNC router

-Arduino prototyping

-Product management

-CAD modeling

-Photorealistic renderings

-Electical schematics + PCB design

-SEO

-Web design

-Fundraising + pitching to investors

Made a redesign of the product + got some cool renders done. Decided that I needed money & just ended up getting a W2 sales job.

I am incredibly passionate about reducing screentime & will definitely return to this project & bring it back to life at some point.